Application scenarios: A hunan power plant company's own steam boiler, boiler exhaust temperature is about 100℃. The flue gas at this temperature is directly discharged into the atmosphere, and higher exhaust temperature causes heat loss. The heat of flue gas at the end of the boiler is recycled through the superconducting heat exchanger, and then the air is heated to reduce the heat loss of the boiler.

Treatment scale: The flue gas volume is 170000Nm³/h and the flue gas temperature is 100℃.

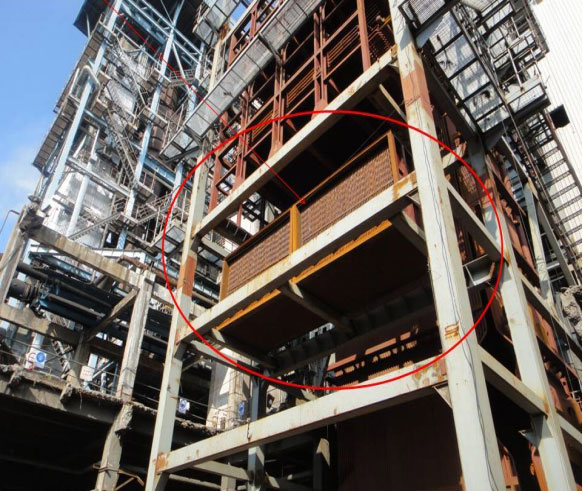

Transformation technology: "Superconducting" technology is used to heat the primary air

Construction scope: Including system design, equipment supply, on-site installation and debugging of the whole Waste Heat Recovery system EPC project (excluding civil construction)

Using effect: The primary air temperature can be raised by about 30℃, and the boiler gas consumption can be saved by about 3%. Operation for one year can recover the investment cost

Bleaching of flue gas of mixer in asphalt plant

Boiler flue gas bleaching

Bleaching of molding machine flue gas

Coking flue gas bleaching

Primary air preheating of boiler

Flue gas waste heat heating demineralized water

Heating oven exhaust air

Dyeing wastewater heating dyeing tank water

Phase change condenser

Natural gas heater

SGH steam heater

High viscosity gas-liquid heater

Drive type air cooler

High efficiency air preheater

High efficiency waste heat recovery device