At present, domestic flue gas desulphurization mostly adopts wet desulphurization process, which can reduce the smoke temperature to about 55℃. The flue gas at this temperature is directly discharged into the atmosphere and condensed into water droplets, forming "white smoke plume" under the refraction of sunlight, causing certain visual pollution to the surrounding residents.

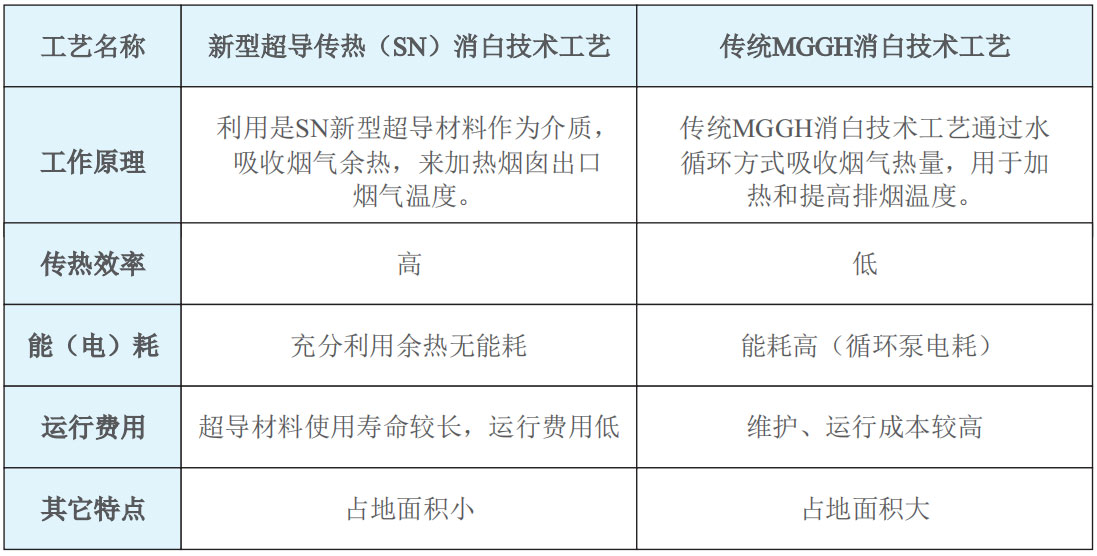

This technical route is to design and manufacture professional flue gas reheat equipment by using the excellent performance of new heat transfer materials. The equipment is different from other equipment, no circulation system, no external energy, the use of boiler flue gas heat, to heat the chimney smoke temperature, has the characteristics of simple structure, small investment, low operating cost.

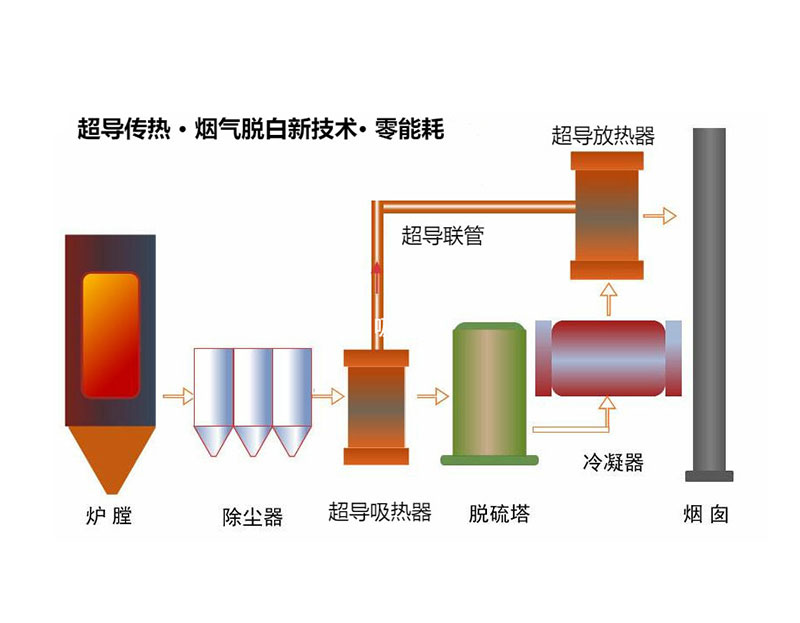

Operating principle diagram

A superconducting heat absorber is arranged between the dust collector and the desulphurization tower, and the high temperature heat here is transferred to the superconducting exothermer through superconducting, so as to heat the terminal flue gas. A condenser is added at the back end of the desulfurization tower to remove part of the moisture in the flue gas. The combination of "condensation + reheat" eliminates the white plume at the chimney outlet.

Bleaching of flue gas of mixer in asphalt plant

Boiler flue gas bleaching

Bleaching of molding machine flue gas

Coking flue gas bleaching

Primary air preheating of boiler

Flue gas waste heat heating demineralized water

Heating oven exhaust air

Dyeing wastewater heating dyeing tank water

Phase change condenser

Natural gas heater

SGH steam heater

High viscosity gas-liquid heater

Drive type air cooler

High efficiency air preheater

High efficiency waste heat recovery device